Oxide Bonded Silicon Carbide(O-SiC)

O-SiC is used for firing general chinaware and ceramic product (temperature below 1,450°C), is made by SiC bonded by Silicon Oxide (Si2O3), and technically called "Oxide Bonded Silicon Carbide". This SiC refractory has very high thermal conductivity (almost 10 times higher than mullite refractory) and high radiation rate of Long-wavelength infrared that bring very high heat efficiency toward products. In terms of cost performance for firing general chinaware and ceramic products, this Oxide Bonded SiC is the most valuable and suitable refractory. Maximum recommended service temperature of our SiC Plate (O-SiC) is 1,450°C. When the application temperature is over 1,450°C, you should choose Recrystallized SiC (Re-SiC) / Max. 1,600°C or Alumina Setter / Max. 1,750°C.

Application

Oxide bonded silicon carbide can be used for ceramics for daily use, Electronic ceramics, sanitary ceramics, Emery wheel, High-pressure electric ceramics, Magnetic material etc.

Ceramic slabs from Carbide Oxide

Specifications of Oxide bonded silicon carbide

|

Typical Quality Analysis |

|

Oxide Bonded |

|

SiC (O-SiC) |

||

|

Max. service temperature(°C) |

1450 |

|

|

Chemical CompositionSiC (%) |

90 |

|

|

SiO2 |

8 |

|

|

Apparent Porosity (%) |

7-8 |

|

|

Bulk Density (g/cm3) |

2.75 |

|

|

Modulus of Rupture |

50 |

|

|

at RT (Mpa) |

||

|

1400°C |

55 |

|

|

Thermal Expansion |

4.2-4.8 |

|

|

at 1000°C (10-6K-1) |

||

|

Thermal Conductivity |

13.5-14.5 |

|

|

at 1000°C (W / mK) |

Product Features

- Excellent high temperature resistant, intensity.

- Excellent thermal shock properties.

- Excellent oxidation resistance.

- Excellent corrosion resistance at high temperature.

- High thermal conductivity.

- High abrasion resistance.

1) Applied to ceramics for daily use

Oxide bonded silicon carbide can offer good heat stability, high mechanical strength at high temperature, excellent thermal stability and distortion resistance at high temperature. It can be used in daily ceramics widely, such as reinforced ceramics, white ceramic and high-class ceramics. Through the burning of 1400℃, its products can offer mild, bright and white enamel feeling, it can save the energy and increase the volume of kiln therefore it can increase the efficiency and economy. At the same time, our kiln furniture is harmless to environment.

2) Applied to sanitary ceramics

Oxide bonded silicon carbide can offer high mechanical strength at high temperature, excellent heat stability, good distortion resistance at high temperature and oxidization resistance. It can be used in high class washing basin, high-class bow and bowl urinal. Through the burning of 1300℃, it provides high enamel and high abrasion resistance. It can keep gloss and quality for 10 years.

3) Aplikace pro užitkovou keramiku

O-SiC ušetří více než 30 % energie, která se používá hlavně pro lustrační palivové pece odstraněním desek ze slinovací domácí keramické pece.

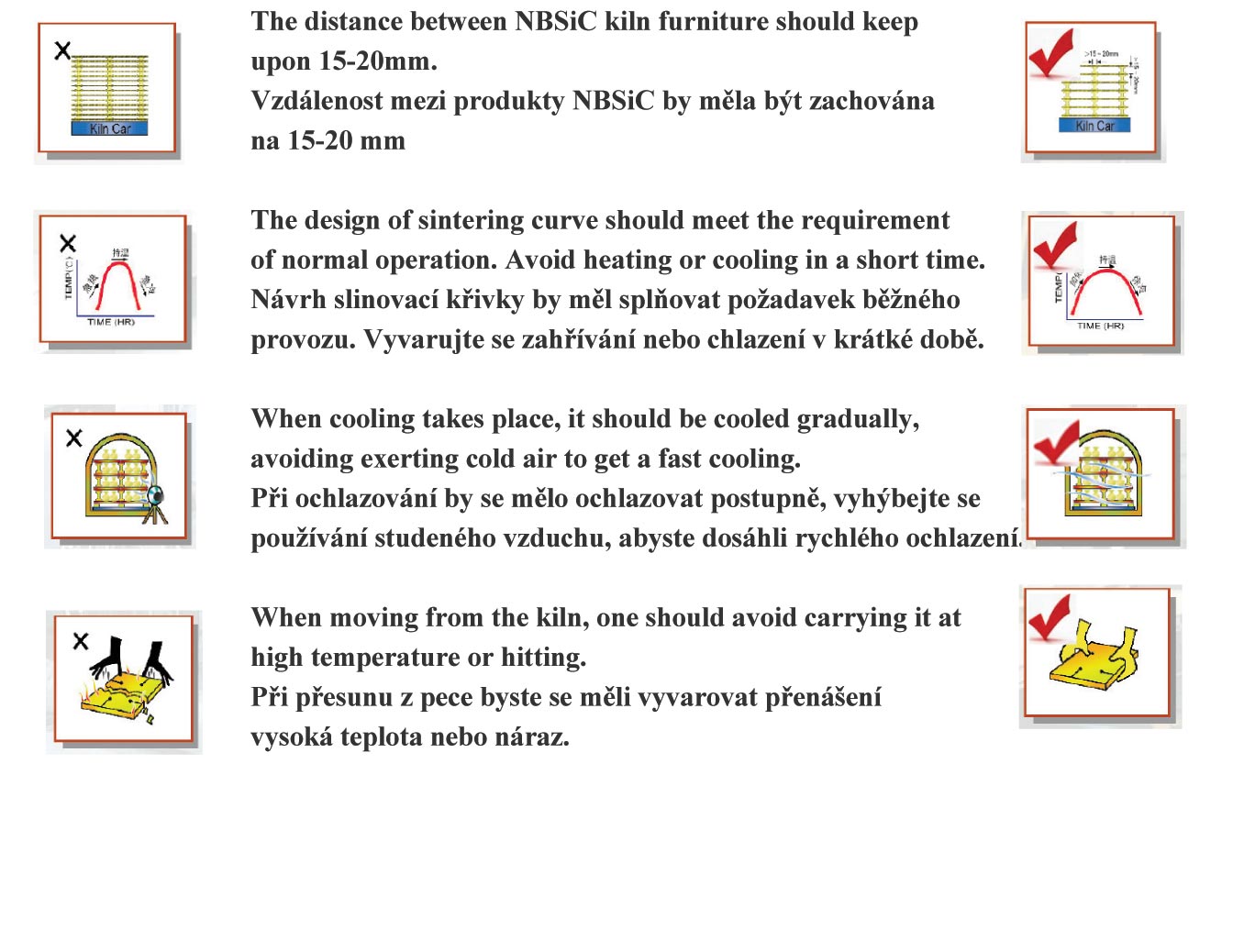

Precaution to the Users